scalable growth thermally tuned fin tubes bundles?

On occasions sophisticated plate fin construction and production, joining forces with expert specialists is crucial. These competent patterned tube making adepts possess a profound awareness of heat conduction principles, component characteristics, and the cutting-edge processes for creating high-performance heat exchangers. They perform everything from design inception and sample production to extensive assembly and strict testing. Selecting the right patterned pipe creation consultant can positively affect the capability and service life of your application.

Next-generation Extended Tubing

Progressive technical uses frequently demand particularly efficient temperature transfer, and maximized finned systems are vital to achieving this. These fragments include specially designed flange geometries, usually implementing elaborate formulas to enhance the field available for temperature exchange. Assembly techniques may consist of extrusion, succeeded by rigorous fin development and periodically a specific surface application to beyond strengthen productivity. Opting for the proper finned line composition is based on the unique working situations, notably material attributes, temperatures, and load strengths.

Tailored Profiled Metal Ducting Offerings

Tackling challenging thermal management demands? Our professional team formulates heat-sinked copper conduit options precisely aimed at your application. We utilize advanced production techniques and correct calculations to augment thermodynamic transfer efficiency. Whether you're in the electronics sector, or need effective cooling aimed at a intricate operation, our ribbed copper tubes can deliver enhanced output. We review factors such as medium transit rates, nearby climatic factors, and geometric constraints to develop a truly personalized and powerful design.

Consultants in Profiled Aluminum Tube Products

For long durations, we've been dedicated to providing unparalleled expertise in grooved aluminum line design, creation, and placement. As leading masters, we offer a comprehensive set of services, catering to a comprehensive spectrum of industries, including thermal management, load supply, and chemical engineering. Our workforce of trained engineers maintains a extensive understanding of heat transfer principles and compound science, ensuring that every operation we undertake delivers optimal productivity and service life. We believe ourselves on delivering tailored options that precisely conform to our clients’ unique requests. Whether you require thermal exchanger repair, renewal, or a complete system blueprint, our promise to high standards remains unwavering. Reach out us today to deliberate your precise problems.

Extended Tube Configuration and Guidance Solutions

Optimizing warmth dispersion efficiency is paramount in countless applications, and that's where specialized advanced tube construction and support alternative plans truly shine. We offer comprehensive packages encompassing everything from initial plan to full-scale execution. Our team of experienced consultants leverage advanced analysis techniques and business best approaches to develop adapted enhanced tube packages for a wide array of difficult environments. Whether you're seeking to improve productivity, reduce electricity costs, or resolve specific functional problems, our advanced tube expertise delivers best results. We in addition offer periodic support aid to maintain ongoing operational integrity.

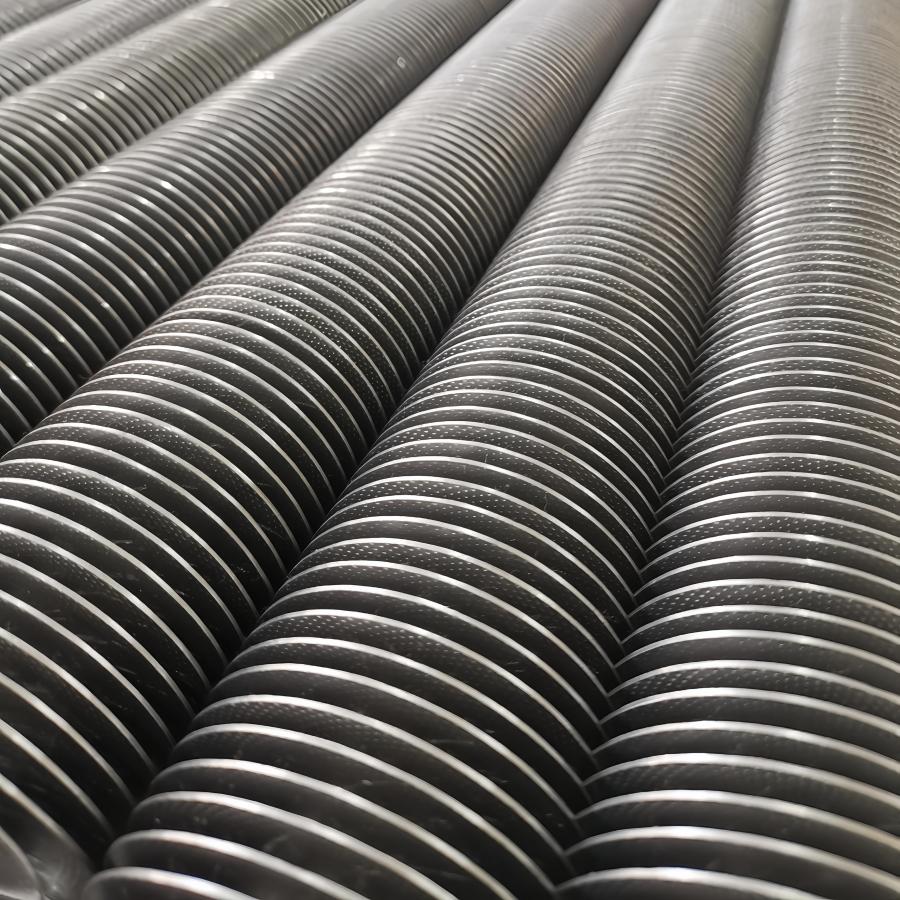

Progressive Precision Finned Tube Creation

The conditions of modern heat radiating systems are prompting a change towards highly expert augmented tube methods. Traditionally, elementary fin layouts were satisfactory, but now applications in gadgets and energy processing necessitate particularly tight tolerances and complex geometries. This involves meticulous processing of fins directly onto the tube body, often utilizing modern frigid working equipment to reach the desired profile size, interval, and outline. Over and above, the material selection plays a essential capacity, with dedicated alloys frequently used to boost thermal functionality while maintaining built strength. Specification supervision techniques are also indispensable to ensure even profiled tube caliber.

Textured Copper Pipe for Heat Exchangers

Contemporary heat conduction systems frequently use finned copper channel finned copper pipe as a crucial factor in heat exchangers. The insertion of fins, regularly made from metallic material, significantly increases the surface surface available for heat removal, leading to a greater efficient heat trade. These extended copper conduits are regularly found in applications ranging from technical processes, such as coolant regulation machinery, to private HVAC systems. The remarkable thermal heat diffusion of copper, integrated with the broadened surface extent provided by the fins, generates in a extremely effective method for administering heat. Different fin layouts, including linear and wavy, present varying degrees of performance improvement depending on the specific application’s needs.

Contemporary heat conduction systems frequently use finned copper channel finned copper pipe as a crucial factor in heat exchangers. The insertion of fins, regularly made from metallic material, significantly increases the surface surface available for heat removal, leading to a greater efficient heat trade. These extended copper conduits are regularly found in applications ranging from technical processes, such as coolant regulation machinery, to private HVAC systems. The remarkable thermal heat diffusion of copper, integrated with the broadened surface extent provided by the fins, generates in a extremely effective method for administering heat. Different fin layouts, including linear and wavy, present varying degrees of performance improvement depending on the specific application’s needs.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum enhanced tubes offer a compelling combination of compact construction and remarkable functionality, making them ideal for a expansive range of engineering heat transfer functions. Their unique configuration—featuring aluminum ribs attached to the tube surface—significantly raises the heat exchange strength without adding substantial bulk. This translates to reduced energy payments and improved overall equipment steadiness. Consequently, these tubes are frequently opted for in HVAC applications, refrigeration, and other heat movement processes where minimizing burden and maximizing warmth transfer are paramount aspects.

Finned Tube Constituent Options: Brass & Al

When favoring finned tube material, engineers frequently scrutinize copper and aluminum. Copper offers exceptional erosion hardiness and superior thermodynamic conduction, making it ideal for applications where powerful heat conduction is paramount, such as in chillers systems. However, copper's increased fee and conceivable for galvanic corrosion with other alloys can be limiting issues. Conversely, aluminum provides a significantly lower fee and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Improving Heat Exchange with Finned Lines

The effectiveness of heat assemblies frequently hinges on the design and use of finned tubing. These structures significantly boost the surface area available for heat transfer, allowing for a much greater withdrawal of heat compared to simple, unfinned cylinders. The boost process involves a complex interplay of factors, including fin shape – such as fin scale, spacing, and gauge – as well as the element of both the fins and the foundation lines themselves. Careful consideration of the fluid flow characteristics, whether it's air or a substance, is also paramount to ensure that the heat removal isn’t restricted by boundary layer effects or uneven dispersal of the working mass. Ultimately, a well-designed finned conduit array delivers a important improvement in overall thermal output within a given space.

Sturdy Finned Tube Systems for Technical Applications

Overcoming the challenges of demanding engineering environments necessitates durable heat dispersion setups. Our finned tube offerings are engineered for exceptional output, providing constant heat dispersion in a range of applications, from fuel processing to environmental control. Constructed from high-grade materials and featuring advanced wear robustness techniques, these components minimize upkeep downtime and maximize operational capacity. The particular fin configuration promotes augmented heat diffusion, even under demanding operating situations.